SERVICING AND MAINTENANCE

IN BIRMINGHAM, AND THE WEST MIDLANDS

EXTINGUISHER MAINTENANCE

It is a legal requirement that fire protection equipment is tested at least annually.

Fire extinguishers should be maintained by a company whose staff are trained, have the correct tools and knowledge and experience to do the job correctly and are insured for efficacy. The servicing of a fire extinguisher is a complicated process and can be dangerous if undertaken by untrained, inexperienced persons.

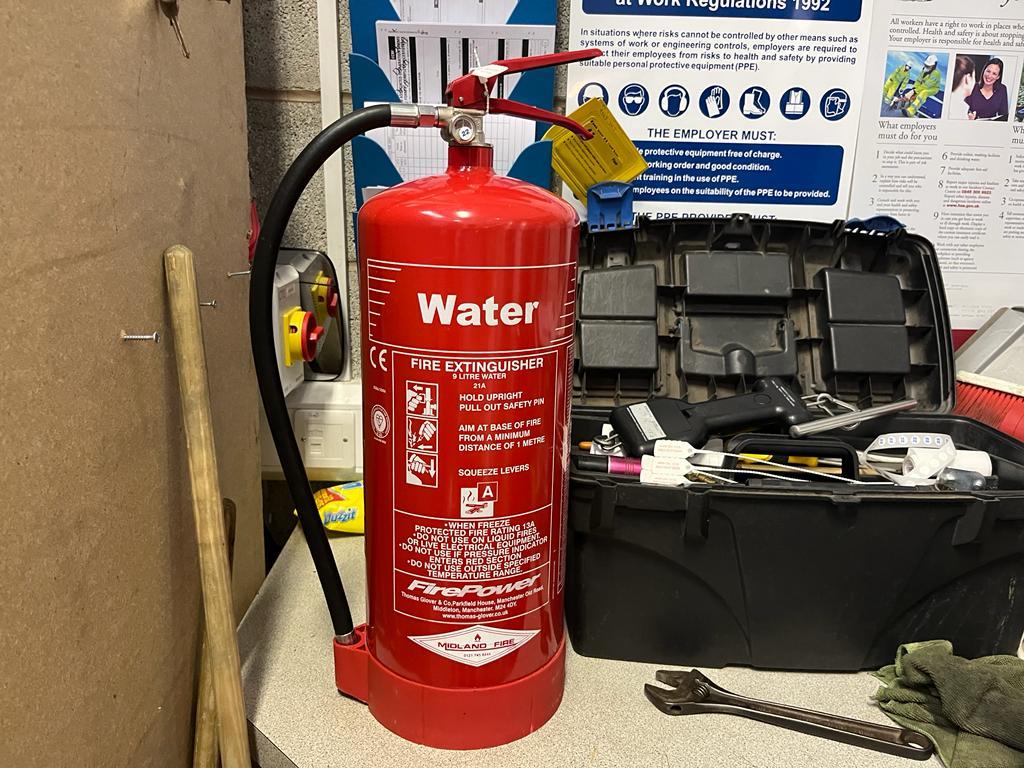

Each of the various types of fire extinguisher has its own purpose and there are a number of things that must be tested every year to ensure that the fire extinguisher would work in the case of a real-fire emergency.

According to British legislation, "All fire extinguishers must be inspected and maintained to BS 5306:3 at least annually. This must be carried out by a "competent person", using the appropriate tools, incorporating any special procedures, which are currently recommended by the fire extinguisher manufacturers".

FREE SITE SURVEY

Midland Fire offer a free, no obligation, site-survey where our engineer will visit your establishment and carry out a full health check of your fire protection equipment, ascertaining the overall quality of your fire extinguishers and equipment, enabling us to provide a quotation to bring everything up to standard.

Our engineers usually carry out the service straight away if instructed to do so, alternatively we can make suitable arrangements to come back at another time if preferred.

(This is available to anyone within Birmingham and the West Midlands catchment area. If you are outside of this catchment, there may be a small charge, only to cover the rising costs of fuel).

BASIC SERVICE

The basic service is carried out at your premises at a time convenient to you, the cost includes any consumable parts that need to be replaced, some of which must be replaced by law each time a service is performed on your equipment, this is usually to ensure no loss of pressure in the extinguishers performance, or "range of throw" (the distance the extinguishing agent is propelled).

All of our prices are subject to V.A.T - charged at the current rate.

WHAT IS INVOLVED IN A FIRE EXTINGUISHER SERVICE

To begin the maintenance of a fire extinguisher our engineers must first check the weight of each extinguisher, we compare this weight to the recorded weight from the previous year or, from the weight when it was installed as new, this gives us an idea as to whether the fire extinguisher has been set off.

Next, in the case of stored pressure fire extinguishers we remove the pressure and then the head-cap, this can be very dangerous if the pressure hasn’t been completely removed and so it is important that when removing the head that it is done out of the way of (human) body parts.

Once our engineer has removed the head-cap assembly, which is what connects to the handle, the hose, and the mechanism (which forces the extinguishant out of the body of the container under pressure), we carefully empty the fire extinguisher of its content, usually into a bucket (in the case of water-based extinguishers) so that our engineers can check the inside of the canister for damage, debris, and signs of aging, or deterioration.

On the inside of every fire extinguisher there is a silicone lining which protects the fire extinguisher from rust, especially as most extinguishers contain a water-based solution, this silicone lining over time can lift away from the body of the extinguisher particularly if an extinguisher hasn’t been annually maintained and the water has become stagnant; often algae can form leading to a deterioration of the silicone itself, causing a bubbling within the interior wall. Obviously if left unchecked this silicone lining and any other debris can get caught in the head-cap thus blocking the extinguishing media from being expelled out of the hose, as intended.

Once we have confirmed that all is in order within the body of the fire extinguisher, we perform a “blow-test” of the hose, making sure that there are no blockages. We then replace all of the O-rings of every seal that has been broken and then replace the extinguishing material back into the body of the extinguisher where it can be re-pressurised. At this point we also perform a check of the pressure gauge to ensure it is working correctly, we then replace the gauge indicator with an up-to-date "sticky dot".

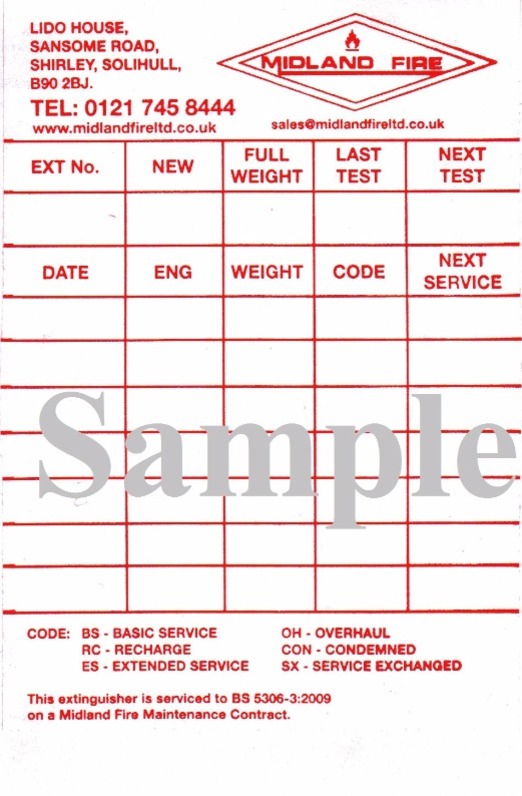

A tamper seal is the last thing we replace, and this is a bit like a cable tie however, unlike a cable-ties the tamper seal is intended to break very easily with very little force. Once the tamper seal has been replaced, we record all of the information on the service label on the rear of the extinguisher and re-hang the extinguisher on its hanging bracket or fire extinguisher stand.

In turn we record all of the information on the service sheet which we use to create the certificate of maintenance for each of our customers premises.

BUYING FIRE EXTINGUISHERS ONLINE

The current British standard (BS 5306-3/2017) stipulates that all fire extinguishing equipment is commissioned on-site, by a *competent person.

When fire extinguishers are purchased from an internet site, cheaper costs do not necessarily equate to a good saving. The reason is that any extinguisher purchased must be commissioned by law.

Mail-orders and internet purchases are often delivered by a person who is unqualified in the theory and practice of servicing portable fire extinguishers and therefore extinguishers will not be ‘commissioned,’ when it is delivered to you. When the extinguishers are dispatched, there could be untold damage, they could potentially have been discharged or lost pressure on the way to your location.

Any damage to extinguishers such as a loss of pressure, loss of extinguishant (i.e. water, co2, foam, powder etc), bent or broken carrying handles, missing or damaged hoses could make the extinguisher inoperable and potentially dangerous, many of these issues can arise in transit to your location, once the supplier has already declared the extinguisher ‘fit for operation’ which could put lives at risk, especially if the supplier has not taken adequate steps to protect the equipment prior to dispatch.

Also, part of the service that Midland Fire provides is to ensure that the correct extinguishers at the correct location for the specific type of fire risk, something which may have been overlooked.

Pre-servicing or pre-labelling is also forbidden because when purchasing fire extinguishers which are to be installed in accordance with BS 5306:3 then they must be commissioned on site, or alternatively they can be installed and commissioned at a later date by an experienced servicing company such as Midland Fire ltd.

Furthermore the “Regulatory Reform (Fire Safety) Order” states that any equipment must be subject to a suitable system of maintenance to ensure that it is in efficient working order and in good repair to be in accordance with the current specification.

Conformity to the current British standard is necessary if you are a business or property owner particularly when a fire risk assessment has to be carried out. Upon completion of the commissioning or servicing procedures the extinguisher must then be positioned and installed in accordance with another British standard B.S.5306-8.

The price of fire protection equipment provided by Midland Fire is not only determined by the basic costs of its production and delivery cost to your address. In order that we maintain our high standard of service, that we are very proud of, we must allow for additional costs such as the cost of vehicle purchase, extinguisher parts, administration costs, fuel, tools, training, spare parts and of course our qualified, and experienced technicians who are fully capable of maintaining all types, sizes, and manufacturers of fire protection equipment.

*A competent person is a someone qualified, has relevant training and experience. They must have the correct tools, equipment and information, manuals and knowledge of any special procedures recommended by manufacturers of extinguisher, to conduct the maintenance procedures.

CERTIFICATION OF FIRE SAFETY EQUIPMENT IN BIRMINGHAM AND THE WEST MIDLANDS

CERTIFICATION

Upon completion of the service and once payment has been made, a certificate of maintenance will be issued listing the quantity and types of fire extinguisher that have passed inspection. This certificate can be displayed in your premises offering at a glance the date it was passed and when your certificate expires. Giving you compliance to the current British standards. Should a member of the fire brigade do a spot check they will be satisfied you are fulfilling your responsibility to the law.

OUR SITE SURVEY WILL TELL YOU:

What types of fire equipment are most suitable for your premises based on floor area/layout and the specific fire hazards or additional risks.

The quantity, type, and size of fire extinguishers or other fire safety equipment required based on the level of risk.

Where the fire equipment should be positioned within your site.

OTHER FACTORS WE CONSIDER:

Possible effects on health and safety of the operator when the equipment is used.

Adverse effects or contamination of the manufacturing processes or equipment of particular extinguishing media (content).

Other effects on the local environmental which could be caused by an extinguisher, or it's extinguishing media (content).

PORTABLE APPLIANCE TESTING NATIONWIDE

Portable Appliance Testing

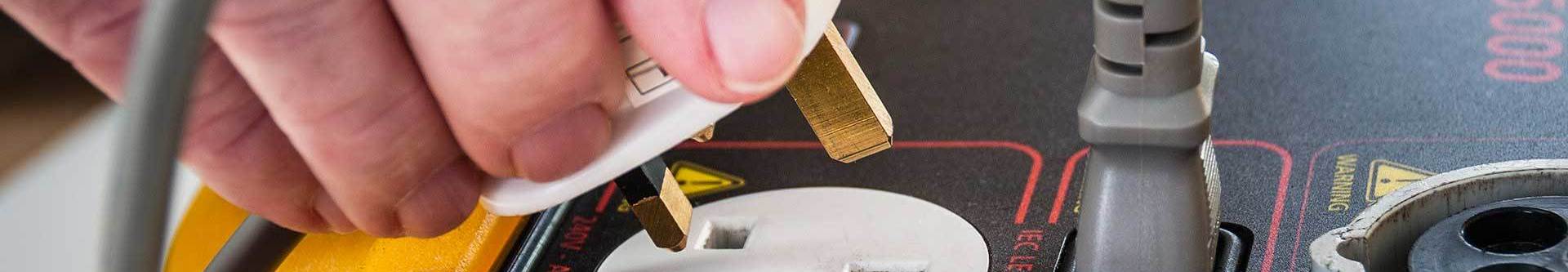

"PAT", is a safety test of all electrical appliances. It is a legal requirement for all employers and Landlords to ensure that appliances are safe and well maintained. The Electricity at Work Regulations of 1989 places responsibility of ensuring all appliances within the workplace are safe to use. Compliance can be achieved by a regular test programs which we tailor to meet your requirements.

SITE SURVEYS

PAT Testing is the process of testing all electrical appliances both visually and manually to determine if they are fit to use.

We undertake the testing and inspection of in-service electrical equipment to ensure all users are suitably protected from potential danger. This is conducted in compliance with the Electricity at Work Regulations 1989, Health and Safety at Work Act 1974, insurance requirements and HSE Code of Practice for the In Service Inspection and Testing of Portable Appliances.

You will be issued with an asset register detailing all appliances tested including test results and any comments or recommendations. Each appliance will be labelled and given a unique identification number

Our experienced portable appliance assessors will test:

Signs of damage to both the supply cord (IEC lead) and appliance

Switch functionality

Correct fuse fitting and type

Live, Neutral and Earth wire integrity

Inspection of the plug and leads

Finally they will conduct a thorough examination of all of the relevant factors.

Midland Fire will then provide you with full documentation to prove that your portable appliance test has been completed and that your establishment is compliant to the current British standard.